(Tiếng Việt) Màng Varnish Transfer NewFilm – giải pháp phủ chống trầy bóng, mờ cao cấp, thân thiện môi trường, thay thế cán màng nhựa, phân phối chính hãng bởi GUDi Việt Nam.

(Tiếng Việt) Varnish gốc nước NewFilm – giải pháp hoàn thiện bề mặt thân thiện môi trường, chống trầy, không rạn nứt, phù hợp ép nhũ. Phân phối chính hãng bởi GUDi Việt Nam.

(Tiếng Việt) NewFilm tiên phong công nghệ ghép màng nhiệt và ghép ướt, cho bề mặt trong suốt, bền đẹp, đạt chuẩn FDA & EU, phân phối chính hãng bởi GUDi.

GUDi welcomed hundreds of visitors and hosted live product demonstrations right at its booth, allowing attendees to experience the quality and real-life applications of its products firsthand.

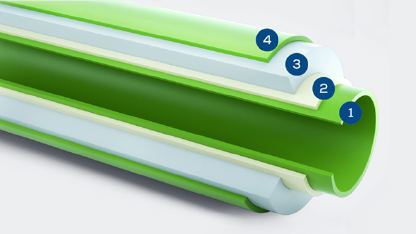

The addition of Rubber Sealed Edges decreases wear and tear of the sleeve while increasing durability. The edges are impact-resistant, therefore the chances of impact damage on the side of the sleeve are reduced.

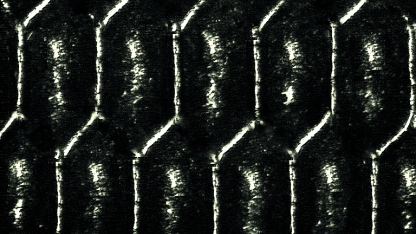

The majority of cold foil jobs are being produced in flexographic printing by using an UV-curing cold foil adhesive which is applied with an anilox roller in a specific volume via a polymer plate onto a substrate.

Building a durable sleeve that lasts takes careful use of the right materials, the right construction method and bringing it all together.

To take full advantage of recent improvements in the flexographic process, printers must understand both their anilox screen specifications – line count and volume – and engraving type and cell geometry.

John Tucker, sales director at Zanders, highlights the key properties of label paper for the special requirements in the beer and mineral water bottling industry.

Manufacturers detail the latest technical developments in packaging films, and explain what label converters need to know when handling the next generation of packaging films.