Choosing the right anilox

To take full advantage of recent improvements in the flexographic process, printers must understand both their anilox screen specifications – line count and volume – and engraving type and cell geometry.

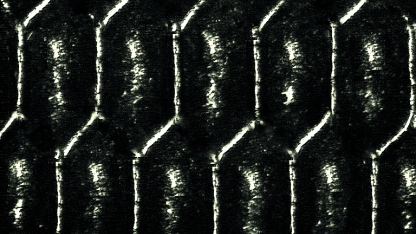

60 deg Hexagonal engraving

Although the 60 degree hexagonal pattern was until recently the most common anilox engraving, it has important limitations with regard to ink release and ink flow. The 60 deg pattern consists of millions of individual hexagonal cells engraved across the surface of the anilox roll. With closed-cell configuration air gets trapped with every rotation, causing turbulence within the ink. This turbulence causes micro foaming and uneven laydown of ink to the plate and substrate, resulting in pin holing. At high speed a loss of color density is caused by the inability of the closed hexagonal cells to get refilled in each revolution. Poor ink release is another major restriction. Due to its conical profile, the 60 deg cell only releases 60-70 percent of its total volume. Problems arise when the unused ink congeals or dries, plugging the cells and causing print inconsistencies.

Today’s advanced laser technology, however, has enabled anilox suppliers to develop superior engravings for a wide range of different applications.

Solid and combination print

With solid and combination print, MaxFlo+ is the best option. The ink release properties of this high line count engraving ensure enough volume is delivered to achieve dense solids and extremely clean vignettes.

Substrate type and ink system affect the anilox specification and engraving type, so having well-defined print targets with tolerances will help your anilox supplier recommend the best solution.

MaxFlo+ is best used for combination UV printing, with volumes ranging from 6-7cm3/ m2 and a high line count of 800-900LPI. The channel improves the ink flow and reduces aeration, which results in significantly less pin holing or voids in the print.

HD flexo printing

HD flexo is a major driver in today’s flexographic industry, and new anilox screening technology has been critical to its success. There are three main factors:

- New fiber optic laser technology has enabled line counts in excess of 2000 LPI compared to the maximum of 1200 LPI by CO2 lasers. The narrower beam width and customized software have made possible sophisticated cell shapes that offer outstanding ink release properties at ultra-fine line counts.

- Changes in ink flow and constitution. Newer finely ground ink pigments allow for greater color strength at lower cell volumes.

- New digital HQ or HD plates have allowed unprecedented refinement of the plate screen. An HD plate is made up of a number of variable dot sizes and support dots on the plate, allowing for plate screens with high LPI and highlight dots that are less than 1 percent.

To make a successfully recommendation, your anilox supplier will need to know the type of ink, substrate, plate DPI and target minimum dot percentage.

Consistency and repeatability of HD process print are critical, and due to the finer anilox required, we recommend ProFlo, which has an improved cell profile that provides a more consistent and controlled ink lay-down to the plate. This high-release cell offers as much as 15 percent additional ink compared with conventional 60 degrees engravings, enabling the anilox manufacturer to deliver the required color densities at finer line counts.

Keeping the anilox cell opening equal to or less than the minimum dot diameter will ensure clean printing as the anilox will deliver the right amount of ink to the plate and not over-ink your minimum dots, avoiding ‘dirty’ printing.

For 175-200LPI HD print standardized line counts range from 1200 LPI to 1400 LPI and volumes from 3.5 to 2.0cm3/m2 in both wide and narrow web printing.

Fixed palette

With demand for shorter runs increasing, fixed palette printing is emerging as a cost effective solution. This technique uses only CMYK plus orange, green and violet or red green and blue, avoiding the need for Pantone colors.

Fixed palette or Expanded Color Gamut (EGC) presents some challenges to the anilox supplier, as consistency of all print variables is fundamental. Adherence to volume tolerances and rigorous measurement of the anilox is key, along with a stable ink viscosity maintained throughout the run.

MaxFlo+ and ProFlo are the best choice for ECG. These high release engravings provide a more efficient transfer to the plate, increasing the density throughout the full tonal range which widens the available range of colors and increases the process color gamut.

The best way to determine the most suitable line count and volume for the 4 or 7 color process is testing through a banded anilox roller. Depending on the substrate and inks used, for the four color process, the recommended anilox line count is between 900LPI -1300LPI ProFlo with volumes ranging from 2.5-4.5cm3/m2 and 800-1100LPI MaxFlo+ with volumes ranging from 6-4cm3/m2 for the donor colors (OGV / RGB). Volume tolerances should not exceed 2 percent.

Liaising with your ink, plate and anilox supplier is vital for the successful implementation of ECG.

High opacity whites

For flexo to achieve or exceed opacity levels of rotary screen, a high volume of ink is necessary. Because UV inks are thick and do not flow easily, transferring a high volume can be a challenge, and the higher the volume the more difficult it is to achieve a smooth coverage.

Easyflo HD engraving achieves by far the highest density. This high-release engraving features a 30 degree angle with an open and linked cell design. Channel engravings have been accepted for many years as a proven way of improving ink flow within the anilox, reducing excessive foaming which will result in pin holing.

Recommended cell volumes range from 25 cm3 /m2 –40 cm3/m2, but cell volumes will need to be assessed on an individual basis based on your print conditions. A good starting point is to check the opacity level achieved with any of your high volume anilox rollers or conduct a banded anilox trial if the results were nowhere near your opacity target.

Another important aspect is surface tension. Most films have a very low surface tension which will makes inking difficult. To obtain sufficient wetting and adhesion, pre-treatment just before the application of whites is necessary. The treatment of any film will dramatically alter the surface tension and will enable the ink to wet out and adhere to the surface.

Plate types can make a real difference to the opacity level achieved. Combining EasyFlo HD with texturized solid plates will improve significantly the ink transfer efficiency and increase opacity.

If applying white to an uncoated substrate or carton, consider larger cell engravings such as MaxFlo and volumes ranging from 20-30cm3/m2.

For applications of white solvent-based inks on plastic substrates, MaxFlo+ achieves opacity levels equal to gravure printing. Although screen specifications will depend on your particular print conditions, a volume range of 15-18cm3/m2 has yielded outstanding levels of opacity in flexible packaging.

Specialty inks and coatings

For specialty inks such as fluorescent, photo chromatic, metallic and pearlescent, ink particle size is the key factor for correct anilox specification. A good rule of thumb is to keep the cell opening a minimum of twice the size of the largest particle size. Once the minimum opening has been determined, the cell volume needs to be assessed. This will be chosen in relation to the minimum dry coat weight recommended by the ink supplier.

It is important to understand that heavy volumes of highly pigmented ink do not work well. High volumes require deep engravings which will make the evacuation of the ink pigments more challenging and the cells will easily plug. Choosing an open engraving will improve the ink release as an open cell structure will have a shallower depth promoting ink transfer. For specialty inks and coatings we always recommend TwinFlo, which features raised ‘posts’ between the linked cells that support the doctor blade, while the double channel screen provides a more open structure that increases ink laydown.

This engraving is also recommended for applications of laminates, adhesives and varnishes, as well as the new on-demand tactile varnishes.

Anilox choice will depend on target coat weight, percentage solids and coating density, as well as the application method (gravure coating or standard flexo) and the doctoring method (two roll or chambered system). Having a benchmark is also critical. If you have used any anilox before and have measured the coat weight achieved, this will be very useful information.

Substrate type is another factor that will affect the final coat weight. The recommended volume for uncoated substrates will be higher than for non-porous or coated substrates.

Source: www.labelsandlabeling.com