Direct food contact inks & coatings

GUDi officially distribute DFC (Direct Food Contact) inks & coatings which are formulated to meet European and US regulations for package printing in direct contact with food.

As a safe, non-toxic ink, DFC opens up new possibilities for package design by increasing the available “real estate” for printing. In addition, DFC can replace traditional inks in areas where migration of potentially harmful ink components is of concern. Finally, DFC inks & coatings play an important role in the effort to reduce overall packaging volume; either by eliminating the need for protective laminates or allowing thinner gauge protective films. In this case, improved package safety corresponds with a smaller “carbon footprint” and cost savings. Under the right conditions, DFC inks & coatings can also help packaging comply with compostability standards (EN13432).

DFC inks & coatings are available in flexographic and gravure versions and in a broad palette of colors.

Spring’s DFC ink technology eliminates health concerns over migration and helps to guarantee the essential integrity of the food itself. DFC technology works on three levels which, combined, can respond to virtually any packaging application.

The table below gives some suggestions for adopting the DFC technology best suited to your packaging application:

| LEVEL | DRY FOODS | FATTY/GREASY FOODS | HUMIDITY | CHOCOLATE |

| DFC Ink on film or paper | +++++ | +++ | ++ | ++++ |

| DFC Ink on film or paper with protective DFC varnish | +++++ | ++++ | +++ | +++++ |

| DFC Ink on film or paper with thin protective film | +++++ | +++++ | +++++ | +++++ |

Level 1: DFC inks with no functional barrier- primarily for contact with dry foods;

Level 2: DFC ink + DFC protective varnish- an inexpensive solution for improved mechanical, humidity and chemical resistance;

Level 3: DFC + thin-film food laminate. With a traditional ink, even a “low migration” ink, a film laminate is not a fail-safe guarantee against the migration of harmful substances. Since DFC does not contain any harmful substances, a thin barrier film (in most cases 12µ is sufficient) provides a reliable barrier to eliminate risks of bleeding due to direct contact with greasy, fatty foods or humid conditions.

GUDi & Spring works directly with its customers to identify the best solution for every packaging challenge.

RELATED PRODUCTS

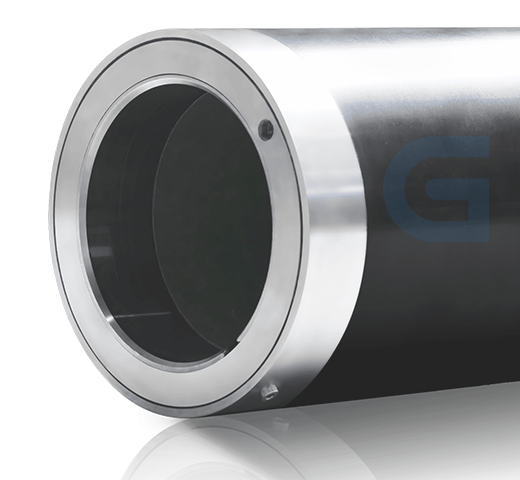

Flexographic Printing Sleeves

Flexographic printing sleeves are used to mount printing plates. They have a major influence on the efficiency & the quality of the print

Made in Neitherlands

Flexographic Printing Bridges

Flexographic bridge/adapter is used in the flexo printing to ‘bridge’ the gap between a printing mandrel and the inner diameter of the printing sleeve, especially for big repeat sleeves.

Made in Netherland

EF Cooling EVO Series chillers

EF Cooling EVO Series chillers are advanced cooling systems specifically designed for use with digital presses, particularly HP Indigo presses.

Made in Switzerland