Univacco Hot Stamping Foil

1. What is Hot Stamping Foil?

Hot stamping foil, also known as stamping foil, metallic foil, can be transferred to substrates with heat and pressure using metal dies. Hot stamping foil is unique in being able to offer incredible metallic shine, bright, mirror-like finishes to design. Differ from metallic ink printing, foil after the stamping process (foil blocking print method) creates a level of luxury.

2. Our Hot Stamping Foils

Univacco supply a wide range of hot stamping foils for many substrates or materials, which are: coated paper, UV-vanished paper, water-base-vanished paper, uncoated paper, dry paper, carton, plastic self-adhesive label, OPP, PET laminate, PVC-based book cover, PU-leather and other synthetic leather.

3. Why Choose Hot Stamping Foil?

Univacco’s hot stamping foil allows excellent release and creates consistent printing performance, which is suitable for either the fine detail or large area coverage.

Hot stamping foil from Univacco can run through all stamping machine types of the market known manufacturer in the graphic industries on Up-and–down/platen/clamshell/letterpress presses, on cylinder presses and on rotary stamping systems.

4. Univacco hot stamping foil ranges & features:

705: Universal foil with standard quality.

717: Universal foil suitable for various substrates and some UV varnishes

727: High speed foil for rotary equipment

730: Versatile foil for packaging and labelling applications

777: Foil for extremely fine design & small area coverage

OF-06: Over-printable foil with conventional and most of UV-inks

RS-01: Very high speed foil for rough surfaces with good coverage

5. Hot Stamping foil 705

Universal foil with standard quality

| Main characteristics |

|

| Substrate |

Plain paper, cardboard, printed paper, embossed paper, coated paper, some PP/PE/PVC labels and OPP film laminates

|

| Recommended applications |

Wine and spirit boxes, labels, cigarette packages, cosmetic packaging boxes, greeting cards other applications in graphics industry.

|

| Relevant equipment |

Vertical, Clam-shell ,Cylinder and Rotary machines

|

| Operating hints |

|

| Availability |

Gold/Matte Gold, Silver/Matte Silver and dark shades are available, please check color chart

|

About Univacco

Univacco has 6 production sites and over 600 employees around the world.

Univacco is one of the most professional vacuum and coating firms in the world, providing various decorative and functional foils which covered hot stamping foils, cold foils, holographic foils, and digital foils. Immerse your products in the vibrant array of colors of our foils and as portrayed by the Univacco rainbow logo, shower a rainbow of affection on your customers.

QUALITY MANAGEMENT SYSTEM

Univacco guarantees consistent quality, efficient utilization of capacity, and rationalized system during all stages of the business, from development, procurement of raw materials, production, and packaging. The ISO 9001 system has implemented since 2000, based on this, Univacco was certificated to ISO 14001, ISO 50001, ISO 45001, and ISO 14064 consistently. Product quality is inspected at each stage of production in accordance with relevant quality inspection criteria and certifications.

CERTIFICATIONS

ISO 45001:2018 – Occupational Health and Safety Management Systems

ISO 50001:2018 – Energy Management System Standards

ISO 14001:2015 – Environmental Management Standards

ISO 14064-1:2018 – Greenhouse Gas Verification

ISO 14067:2013 – Product Carbon Footprint Verification

CONTACT:

GUDi is authorized distributor of UNIVACCO for its products in the market of North & Middle of Vietnam. Please feel free to contact us for supporting on product guideline, sample & quotation.

- GUDi Company Limited

- Add: 42 No. 2 Street – Cu xa Dien luc, Truong Tho Ward, Thu Duc City, Hochiminh City, Vietnam

- Tel: 0286 286 8801

- Email: hiep.nguyen@gudi.vn

- Hotline: +84906 662 990

RELATED PRODUCTS

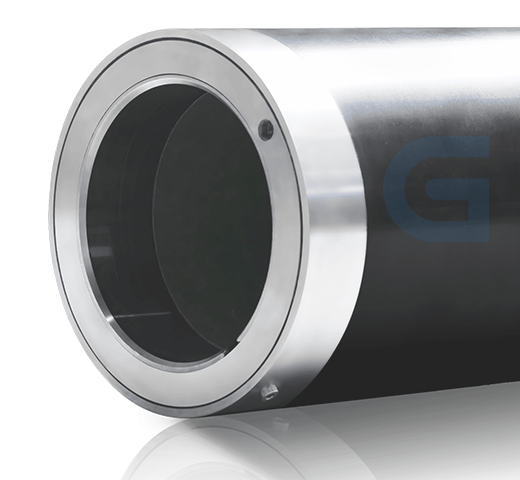

Flexographic Printing Sleeves

Flexographic printing sleeves are used to mount printing plates. They have a major influence on the efficiency & the quality of the print

Made in Neitherlands

Flexographic Printing Bridges

Flexographic bridge/adapter is used in the flexo printing to ‘bridge’ the gap between a printing mandrel and the inner diameter of the printing sleeve, especially for big repeat sleeves.

Made in Netherland

EF Cooling EVO Series chillers

EF Cooling EVO Series chillers are advanced cooling systems specifically designed for use with digital presses, particularly HP Indigo presses.

Made in Switzerland